5 Important Things to Check if Your Forklift Doesn’t Start

As with all complex machinery sometimes forklifts can experience problems that may prevent it from starting.

There are several reasons a forklift may not start some of them easily identifiable and fixed, whilst others are complex and require a high level of knowledge and skills from a trained technician to identify and fix.

In this post we briefly look at five key things to check in the event your forklift doesn’t start up.

1. Is the forklift fueled up or the battery charged?

It might seem obvious but many an operator has forgotten to check their forklifts fuel level (LPG, petrol & diesel models) or if the battery is charged (lead acid and lithium models).

For combustion engine forklifts it is important to check that there is enough fuel available for the unit to operate.

If the forklift is an LPG unit it is also important to check that the gas bottle has been fitted and connected properly, particularly checking for any holes or kinks in the hose line that may allow gas to escape or its flow.

For battery electric forklifts it is important to check that the battery is holding charge to power the unit.

It is also important to double check charger connections to ensure it is properly charging the battery in preparation for the next shift.

2. Is the emergency button engaged?

Most modern battery electric forklifts are fitted with emergency stop buttons.

Emergency stop buttons are large red buttons that are in prominent and easily accessible positions on the operator console or bonnet for the operator to pull in an emergency to stop the forklift.

Checking if a forklifts emergency stop button has accidentally been engaged and turning it off is a simple check and fix if your battery electric forklift isn’t starting up.

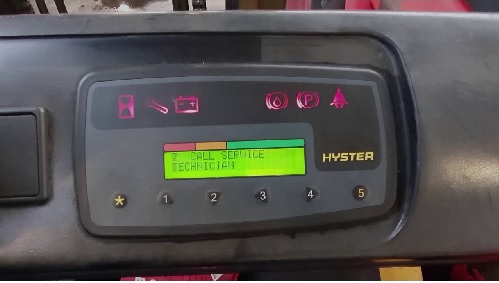

3. Are there any warning lights being displayed?

Modern forklifts are fitted with several warning and safety features to tell operators there is a particular problem with the unit.

If a forklift isn’t starting up one of the first things that should be checked is the operator dashboard for any warnings being displayed.

Some forklifts have specific lights on the dashboard that illuminate to indicate problems with specific systems, some forklifts may have LCD screens that display specific error codes or warnings to the operator.

If a warning light is illuminated or an error code is displayed the first thing an operator should do is determine what the warning or error code means.

All forklifts should be supplied with a manual where manufactures provide detailed lists of common warnings or errors that may occur and how operators can fix the issue, for complex warnings and error codes the manual will usually provide details of who your dealer contact is for trained assistance to fix the issue.

4. Is the forklift in neutral?

Like cars most modern forklifts will not start if the forward/reverse lever has been left in a position other than neutral.

This important safety feature prevents an operator from accidentally starting a forklift whilst in forwards or reverse and for the unit to start moving straight away potentially endangering other staff members or causing an accident due to unexpected movement.

If your forklift isn’t starting it is simple to check if the directional lever has accidentally been engaged if it has been engaged revert it back to its neutral position and try to start the forklift again.

5. Have you completed the start-up sequence correctly?

Some forklifts are fitted with advanced safety systems such as Forktrack from Speedshield Technologies.

As part of these advanced safety systems a start-up sequence may be installed that requires the operator to complete specific actions in a particular order before the unit will start-up.

Some examples of steps involved in a start-up sequence may include:

- Operator must sit on the forklift seat – means the forklift cannot be started up or running whilst there is no operator present

- Operator must put on seatbelt – ensures that the operator is safely secured in the operator cabin reducing the risk of them falling out and injuring themselves in the event of a crash or rollover

- Answer pre-start questions – the operator must read and answer a series of questions regarding the forklifts and checks they have carried out ensuring the unit doesn’t start-up until all compulsory safety checks are completed

- Wait for dashboard to light up – ensure the operator checks the dashboard for any warnings or error codes that need to be rectified before the unit is started

- Turn on Ignition – turn the ignition to start-up the forklift

- Take of the handbrake – the final step in the start-up process so the forklift can move safely

Operators must ensure they complete all the start-up sequence steps in the correct order to be able to start the forklift.

If a step is missed or the sequence is done out of order the unit will not start.

If none of the checks discussed in the post above allows your forklift to start-up then your forklift may be experiencing a complex issue that requires a trained technician to come and inspect the unit and fix the issue.

Adaptalift has over 200 fully equipped service vans, with over 19 service centers and 10 state branches Australia wide, in all metropolitan & major regional areas.

We guarantee industry leading response and efficient service.

Adaptalift has industry leading standards in forklift service and repairs, with highly accredited technicians working to keep your forklifts running.

With over 40 years’ industry experience across all forklift makes and models, you can be confident that Adaptalift is an expert on your forklift.

For all forklift servicing, maintenance and repairs contact our service department on 13 22 54 or fill-out an online service enquiry and we will respond as soon as possible.