5 Warehousing Supply Chain Management Best Practices

Effective supply chain management is crucial for the success of any business, and an integral component of this process is efficient warehousing.

In Australia, where logistics plays a significant role in the economy, adopting best practices in warehousing can provide a competitive edge.

This article will explore five warehousing supply chain management best practices.

1. Embracing Technology for Warehouse Automation

In recent years, technology has revolutionised the warehousing industry enhancing operational efficiency and reducing costs.

Australian companies have recognised the value of warehouse automation systems, such as robotics, artificial intelligence, and warehouse management software (WMS).

According to a report by the Australian Logistics Council, adopting automation technologies can significantly improve order accuracy, inventory management, and overall productivity.

2. Prioritising Inventory Optimisation

Effective inventory management is critical to minimise costs and ensure customer satisfaction.

Australian businesses have been implementing various techniques to optimise their inventory levels.

For instance, adopting just-in-time (JIT) inventory management, where inventory is ordered and delivered as needed, can reduce holding costs and free up valuable storage space for other high demand products.

Additionally, the use of demand forecasting tools and real-time data analytics helps companies accurately predict demand patterns, avoiding stock-outs and overstock situations.

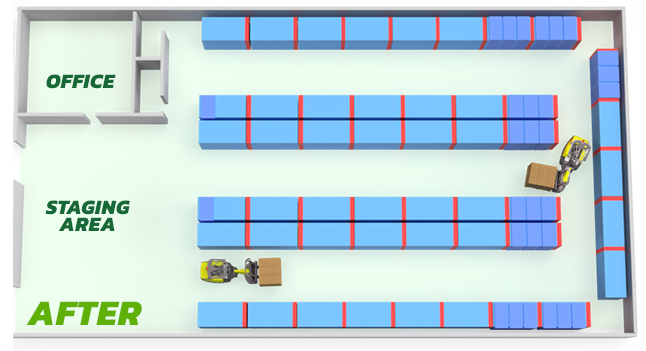

3. Implementing Lean Principles

Lean principles focus on eliminating waste and improving process efficiency.

In the Australian warehousing industry, companies have embraced lean practices to optimise operations.

By streamlining workflows, reducing unnecessary movement, and implementing visual management techniques, companies can improve productivity and eliminate non-value-added activities.

The Warehousing Research and Education Council of Australia emphasises the importance of lean practices in enhancing warehouse performance and customer satisfaction.

4. Enhancing Collaboration and Communication

Clear communication and collaboration among stakeholders within the supply chain ecosystem are vital for effective warehousing operations.

In Australia, industry collaborations and partnerships are actively encouraged to improve supply chain visibility and optimise efficiency.

Initiatives such as the Australian Logistics Council’s Supply Chain Collaboration Project promote better communication and coordination between suppliers, manufacturers, and retailers.

By sharing information and working together, businesses can achieve streamlined processes and reduced lead times.

5. Ensuring Occupational Health and Safety (OH&S) Compliance

Maintaining a safe working environment is a legal and moral obligation for all Australian businesses.

In the warehousing sector, where manual handling and equipment operation pose potential risks, OH&S compliance is of utmost importance.

Organisations need to comply with regulations, conduct regular risk assessments, provide appropriate training, and promote a safety-oriented culture.

The National Transport Commission of Australia emphasises the significance of OH&S compliance to reduce workplace accidents and improve employee well-being.

To stay competitive in the evolving supply chain landscape, Australian businesses must adopt best practices in warehousing supply chain management.

Embracing warehouse automation, optimising inventory, implementing lean principles, fostering collaboration, and ensuring OH&S compliance are crucial steps toward achieving operational excellence.

This article has highlighted five warehousing supply chain management best practices.

By adopting these practices, businesses can enhance efficiency, reduce costs, and deliver superior customer experiences.

Reference List:

- Australian Logistics Council. (2021). Warehousing and Automation: Benefits for Australian Businesses. Retrieved from https://www.austlogistics.com.au/documents/Warehousing-and-Automation-Benefits-for-Australian-Businesses.pdf

- Warehousing Research and Education Council of Australia. (n.d.). Lean Warehouse Operations: Principles and Practices. Retrieved from http://www.warehousingresearch.org.au/wp-content/uploads/2021/06/Lean-Warehouse-Operations.pdf

- Australian Logistics Council. (2022). Supply Chain Collaboration Project. Retrieved from https://www.austlogistics.com.au/supply-chain-collaboration-project/

- National Transport Commission. (2021). Model Work Health and Safety Act and Regulations: Version 1.2. Retrieved from https://www.ntc.gov.au/sites/default/files/assets/files/Model%20Work%20Health%20and%20Safety%20Act%20and%20Regulations%20v1.2.pdf

Please note that while the information provided in this blog post is based on reliable sources, it is important to refer to the original documents for more comprehensive details and the latest updates.