How Much Does a Forklift Battery Cost?

Before spending a large sum of money on a new or replacement forklift battery it is important to clarify some information, so you buy the correct battery for your forklift.

When forklift owners purchase a battery uninformed it can often result in damage or problems with the forklift and the need to purchase a second correct battery shortly after.

Your forklift dealer can help you identify and purchase the correct battery for your forklift.

5 Things to Know Before Buying a Forklift Battery

1. What voltage does your forklift use?

Depending on the type of forklift or materials handling unit the voltage of the forklift can vary (e.g., 36 or 48 volts).

It is imperative to be sure what voltage your forklift uses.

Choosing the wrong voltage battery can not only damage the battery but also your equipment

2. What is the amp hour capacity of the battery?

Check the ampere (Ah) capacity rating on the current battery in your forklift.

To ensure maximum power and run time choose the highest rated amp hour battery approved for your forklift.

3. Measure the battery compartment dimensions

Measure and write down the dimensions (L x W x H) of your forklift’s battery compartment.

Ensure that any new battery purchased will fit into the unit’s battery compartment.

4. Confirm the minimum counterweight requirement

Check the forklifts rating plate or owner’s manual to confirm the minimum battery weight.

Installing an underweight battery can impact the stability of the unit when lifting heavy loads making continued operation extremely dangerous.

5. Check the connector type, cable positions and lengths

You’ll need to know:

- Where the battery connects to the forklift

- How long the battery cable needs to be (if in doubt choose longer cables)

- The colour and position of the connectors

Main Types of Forklift Batteries

Wet Cell / Flooded Lead Acid Batteries

The most economically priced of the three battery technologies.

Their average cycle life is 1500 charge / discharge cycles or 5 years working life.

This type of battery is best used in a single working shift application with 8 hours work, 8 hours charge and then 8 hours cool down

Regular maintenance needs to be performed on this battery including filling with water, cleaning the top of the cells.

This battery cannot be used in food preparation applications.

Dedicated battery charging rooms need to be designed and used with mechanical ventilation (if large numbers of batteries are being used), spill kits, eyewash stations and deluge shower and acid spill containment and collection requirements.

Gel Sealed Maintenance Free Batteries

This battery technology is the mid-tier, costing around 50% more than the flooded battery.

Their average cycle life is 1200 charge / discharge cycles or 4 years working life.

This battery type should be used in a single working shift application with a 12-to-14-hour charge time.

Amp hour capacity of gel batteries is less then flooded batteries so reduced working shift times is expected.

This battery is maintenance free and can be used in food preparation applications.

No dedicated battery charging room is required, as the battery is sealed and does not give off any fumes or gasses when charging unless there are second shift batteries required then, battery roller bed and mechanical battery changing equipment is required.

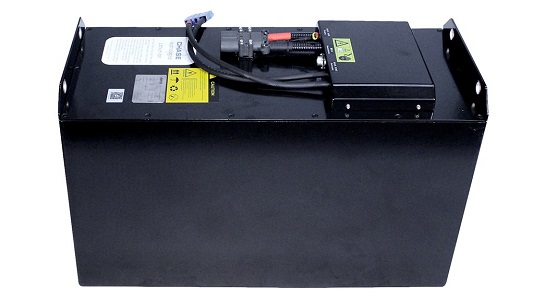

Lithium Fast Charge Batteries

This battery is the premium tier product, costing over double the cost of the basic wet cell / flooded traction battery.

The average cycle life is more than 3500 cycles (well over double the life of wet cell product).

These batteries are teamed with fast chargers allowing the battery to be opportunity charged during downtimes or fully charged in very short amounts of time – if suitable mains power is available, these can be charged from flat in under 1 hour and an average warehouse with standard three phase power outlets will have the battery fully charged from flat in around 2 to 2 ½ hours.

Amp hour capacity is generally calculated at around 70 to 80% of what a flooded battery is due to the ability of not having to limit the discharge of the battery to 80% as a flooded battery must be also there is little to no resistance occurring when charging so, the charge return rates are far purer that flooded or gel battery technologies.

This battery is completely maintenance free and can be used in food preparation applications.

There is no need for a dedicated charging room due to the battery being completely sealed and maintenance free and this battery technology should eliminate the need to have second shift batteries in two shift working applications and – if sufficient break times are available can perform the job of providing 24 hour / 3 shift work applications.

Choosing the correct forklift battery can be complicated due to the wide variety of options available from a large range of suppliers.

It is important prospective buyers considers Ah capacity, chemistry, charging speed, cycle life, brand, price to ensure they purchase the most suitable battery for their forklift.

Our team of forklift experts can assist you in specifying and purchasing a compatible battery for your forklift.

Contact our team on 13 22 54 to answer all your forklift battery questions.