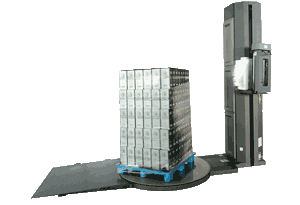

What is a pallet wrapper?

A pallet wrapper, or pallet stretch wrapper, can automatically wrap your pallet in film. The wrap extends to the goods on the pallet, keeping it all safe and secure.

These machines work a lot faster than manual wrapping. Just one pallet wrapper could help you wrap hundreds of loads every day.

When and why should you use pallet wrapper?

You should use an electric pallet wrapper if manual wrapping takes up too much time. Any firm wrapping 30+ pallets per day should look into these machines.

Smaller businesses also use pallet wrappers because they’re cost-effective. For example, they stretch the film while wrapping to ensure each roll lasts longer.

What are the benefits of using a pallet wrapper for packaging?

Pallet wrapping can be time-consuming, and a dedicated machine lets your team focus on their other duties. Boosting your productivity also usually leads to higher profits.

You’ll also reduce human errors; a wrapping machine will get it right every single time. Your pallet will stay secure, lowering the risk of mid-transport damages.

What materials are compatible with pallet wrappers?

These machines fit standard industrial wooden pallets. Each model has a different weight limit, but you can usually wrap 2 tonnes of goods per load.

As for the palletised goods themselves, boxes, bags, and even bottles are suitable for automated wrapping. Make sure your load fits the machine’s height limits.

What is the difference between semi-automatic and fully automatic pallet wrappers?

An automatic pallet stretch wrapper machine automatically attaches the film to a load. In contrast, semi-automatic machines need someone to load the pallet and even attach the film.

Fully automatic machines can use a conveyor belt system to continuously wrap pallets without intervention. However, semi-automatic options may be better for irregular loads.