EWP Inspections When to Complete them and Why they’re Important

Carrying out regular inspections and maintenance of elevating work platforms is integral to ensuring operator safety is maintained whilst also ensuring unit operational longevity.

Under Australian standard AS 2250.10-2006 all EWP units including scissor lifts, boom lifts and telehandlers must undergo a major inspection every ten years from their date of manufacture.

The inspection must be carried out by an appropriately trained and qualified technician and follows a strict inspection checklist looking at components and unit function to ensure the unit is operating at optimal levels.

As well as testing unit functions one of the main aims of the inspection is to look for and immediately replace any components showing signs of wear, fatigue or corrosion.

This week’s blog highlights the different types of inspections by law are required to be undertaken throughout a EWP unit’s life cycle.

There are four types of inspections that need to be undertaken on a regular basis to ensure EWP’s are safe and functioning to optimal levels:

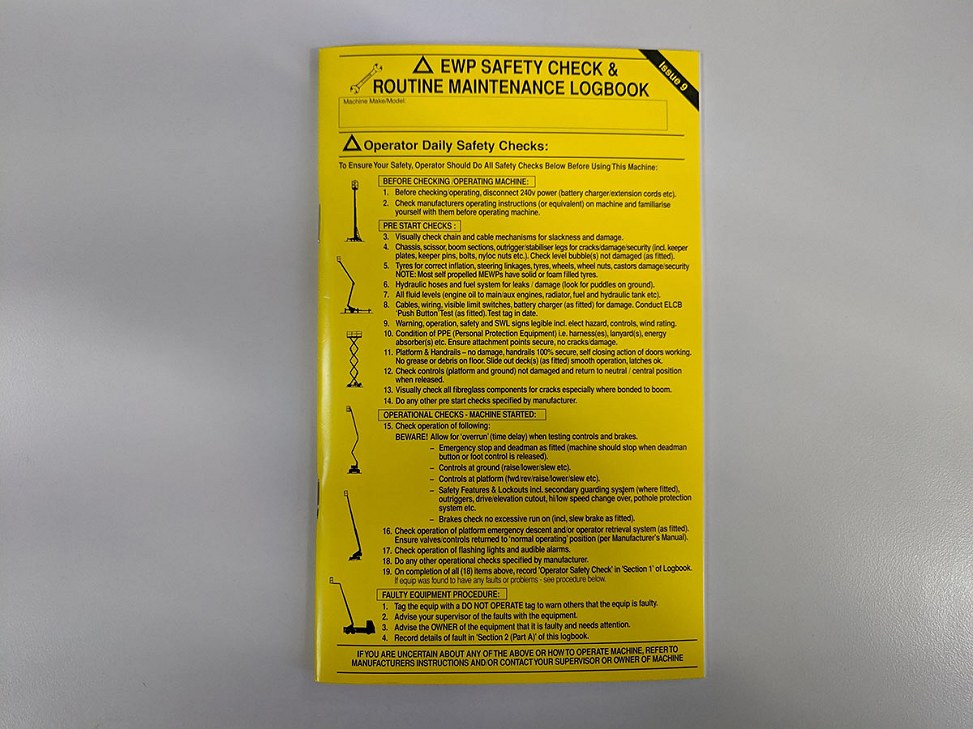

- Pre-operational inspections

- Routine inspection and maintenance

- Periodic inspection

- Major inspection

Pre-operational Inspections

- Must be carried out by a qualified operator before the beginning of every work shift in accordance with Australian standards

- Includes visual inspections for broken equipment, wear, fatigue or corrosion of major components

- Includes control testing of operational speed and smoothness and range of motion

- Includes functional testing of all safety and emergency systems including interlocks and emergency lowering systems

Routine Inspections

- Routine inspections and maintenance must be completed by a qualified inspector in time-frames not exceeding three months in duration.

- The inspector will verify the units logbook and operator manual are up to date

- Includes visual inspections for broken equipment, wear, fatigue or corrosion of major components

- Control functions and safety devices are tested including ground based basket controls

- All hydraulic hoses and connections, chains and cable mechanisms are inspected for breaks, wear, fatigue or corrosion

- All moving parts should be lubricated

- Fluid levels and filter checked

- Written inspection report provided after inspection with any points of action

Periodic Inspections

- Periodic inspections must be completed by a qualified inspector based on EWP’s working environment, usage frequency and work load but shall not exceed twelve month intervals

- More in-depth inspection than a routine inspection that may include the dismantling of parts to check they’re still fit for purpose and don’t need replacing

- EWP’s with flexible suspension must have and pass a stability test in fifth year of operation and every two years thereafter

- Unit is not to be returned to service until all relevant parts have been replaced and all safety and operational malfunctions and problems have been rectified and signed off by a qualified inspector

Major Inspections

Major inspections and subsequent required maintenance must be carried out if any of the following criteria are met:

- The unit hasn’t been subjected to a routine and periodic maintenance regime and has been operational for ten or more years

- Units that have completed a ten year major inspection and have been operational for a subsequent five year period since

- EWP’s that have been imported or re-commissioned and do not have any previous maintenance records

- Normally involves a full strip down of the unit and its components

- Any paint, grease and corrosion from all components must be removed

- Complete visual inspection of all unit components including structural welds

The diagrams below highlight the critical areas of both boom and scissor type units that need to be inspected.

- Tyres need to be inspected for excessive wear or damage

- Inspect bolts for security

- Inspect all boom arm components for damage and cracks

- Inspect all rams for leaks, damage and security

- Inspect boom pins for degredation, damage and security

- Inspect basket and all mounts for cracks, corrosion, damage and security

- Ensure all audible alarms and emergency systems are operational

- Tyres need to be inspected for excessive wear or damage

- Check pothole protection and stabilisers

- Inspect all scissor arm pins

- Inspect all rams for leaks, damage and security

- Inspect boom pins for degredation, damage and security

- Inspect basket, anchor mounting points and all mounts for cracks, corrosion, damage and security

- Ensure all audible alarms and emergency systems are operational

Adaptalift Groups fleet of fully qualified and trained field service technicians are able to complete all routine, periodic and major EWP inspections on-site with minimal disruption to operations.

This ensures units are operating at optimal levels at all times, whilst ensuring operator safety is never compromised.

To book an EWP inspection, service or repair contact our team on 13 22 54.

Reference List

- Guidance on Major Inspections – for owners and service providers. (2019). 1st ed. [ebook] Elevating Work Platform Association of Australia, pp.1-12. Available at: www.ewpa.com.au [Accessed 14 Oct. 2019].

- Worksafe.vic.gov.au. (2019). Maintenance and inspection of mobile elevating work platforms (MEWPs) in the agriculture industry: Information for employers – WorkSafe. [online] Available at: www.worksafe.vic.gov.au [Accessed 14 Oct. 2019].