What is the Bullwhip Effect? Understanding the concept & definition

Through the numerous stages of a supply chain; key factors such as time and supply of order decisions, demand for the supply, lack of communication and disorganisation can result in one of the most common problems in supply chain management. This common problem is known as the bullwhip effect; also sometimes the whiplash effect. In this blog post we will explain this concept and outline some of the contributing factors to this issue.

What is the bullwhip effect?

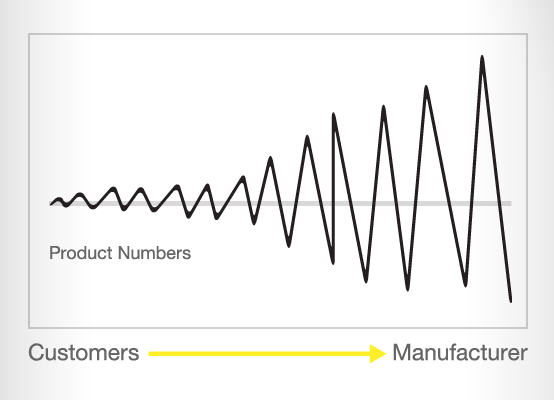

The bullwhip effect can be explained as an occurrence detected by the supply chain where orders sent to the manufacturer and supplier create larger variance then the sales to the end customer. These irregular orders in the lower part of the supply chain develop to be more distinct higher up in the supply chain. This variance can interrupt the smoothness of the supply chain process as each link in the supply chain will over or underestimate the product demand resulting in exaggerated fluctuations.

What contributes to the bullwhip effect?

There are many factors said to cause or contribute to the bullwhip effect in supply chains; the following list names a few:

- Disorganization between each supply chain link; with ordering larger or smaller amounts of a product than is needed due to an over or under reaction to the supply chain beforehand.

- Lack of communication between each link in the supply chain makes it difficult for processes to run smoothly. Managers can perceive a product demand quite differently within different links of the supply chain and therefore order different quantities.

- Free return policies; customers may intentionally overstate demands due to shortages and then cancel when the supply becomes adequate again, without return forfeit retailers will continue to exaggerate their needs and cancel orders; resulting in excess material.

- Order batching; companies may not immediately place an order with their supplier; often accumulating the demand first. Companies may order weekly or even monthly. This creates variability in the demand as there may for instance be a surge in demand at some stage followed by no demand after.

- Price variations – special discounts and other cost changes can upset regular buying patterns; buyers want to take advantage on discounts offered during a short time period, this can cause uneven production and distorted demand information.

- Demand information – relying on past demand information to estimate current demand information of a product does not take into account any fluctuations that may occur in demand over a period of time.

Example of the bullwhip effect

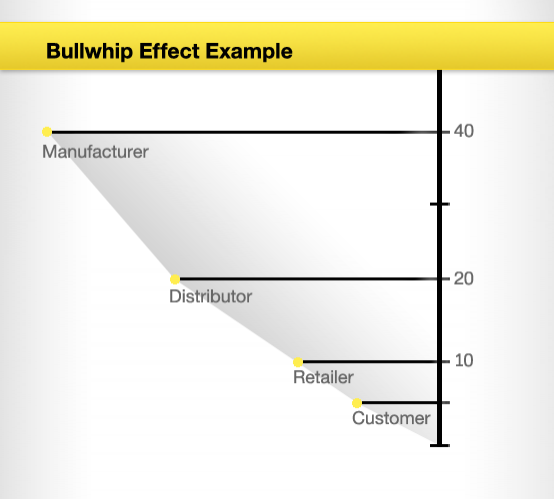

Let’s look at an example; the actual demand for a product and its materials start at the customer, however often the actual demand for a product gets distorted going down the supply chain. Let’s say that an actual demand from a customer is 8 units, the retailer may then order 10 units from the distributor; an extra 2 units are to ensure they don’t run out of floor stock.

The supplier then orders 20 units from the manufacturer; allowing them to buy in bulk so they have enough stock to guarantee timely shipment of goods to the retailer. The manufacturer then receives the order and then orders from their supplier in bulk; ordering 40 units to ensure economy of scale in production to meet demand. Now 40 units have been produced for a demand of only 8 units; meaning the retailer will have to increase demand by dropping prices or finding more customers by marketing and advertising.

Although the bullwhip effect is a common problem for supply chain management understanding the causes of the bullwhip effect can help managers find strategies to alleviate the effect. Hopefully this blog post has given you a simple understanding of the term.