Fleet Replacement and Lifecycle Management

What is Fleet Management?

Fleet management a term used to describe the management of a company’s transportation fleet. Fleet management includes commercial motor vehicles such as cars, ships, vans and trucks as well as forklifts and other machinery used to transport goods. Fleet management is a function which aims to reduce the risks associated with vehicle or machinery investment, improving efficiency, productivity and reducing overall costs whilst complying with government legislation on topics such as duty of care throughout the process.

What is Lifecycle Management?

Lifecycle management involves managing all the various expenses (and revenue) components involved in providing and operating a vehicle throughout its operational life. Lifecycle cost elements include acquisition, license, insurance, fuel, maintenance, repair, salvage, debt expense, administration, accidents, inventory, and downtime.

All too often companies ignore the expense of lifecycle cost elements which results in utilising equipment for a lot longer than they should. Businesses continue to repair their forklifts rather than replace them which may ultimately increase costs as more is spent on maintaining old forklifts rather than replacing them with new more efficient ones.

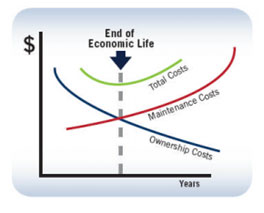

Many also fail to take into account the hidden cost of decreasing productivity levels of the forklifts. Downtime, due to non-productivity of forklifts, results in a loss of income and should therefore be avoided if possible. Based on an economic life cycle model (shown below), a materials handling asset may be subjecting you to higher costs per hour and reduced productivity.

It is however important to note that the optimal time to replace forklifts is rarely a precise moment, but more closely resembles a window. Where that optimal window falls on a forklift or other materials handling equipment’s life can vary between organisations. To determine the optimal window, age and use must be taken into consideration.

Planned Fleet Replacement is Key to Success

A key component of any successful fleet management program is a planned replacement strategy. As a general rule, forklifts have an economic life of approximately 10,000 to 12,000 hours. Again, this varies based on organisation, maintenance practices, operating conditions and the type of equipment used.

Every operating and ownership situation and application is different. It is important that an experienced and knowledgeable fleet management professional evaluates all relevant costs and determines the optimal replacement point for forklifts in a given application or operating environment. Substantial cost savings are available through the implementation of a fleet management program that incorporates the philosophy of planned fleet replacement once a unit has reached its Optimum Economic Replacement Threshold.

In order to run an efficient and productive operation, lifecycle management must be achieved as ultimately the timely replacement of machinery is crucial to the success of an organisation. Lifecycle management results in the avoidance of costly maintenance procedures as well as a contribution to loss of profits due to downtime and delays by inefficient forklifts. By replacing your forklifts at the optimal economic time, productivity and profits can increase within your business.