Are You Using the Right Forklift Tynes for the Job?

When it comes to forklift safety and performance, one of the most overlooked components is also one of the most critical the tynes (also known as forks). These are the primary contact point between your forklift and its load, getting them wrong can lead to damaged goods, compromised safety, and costly downtime.

So how do you know if you’re using the right forklift tynes for your application?

In this guide, we’ll break down tyne terminology, types, and key safety tips to ensure your equipment stays compliant and efficient.

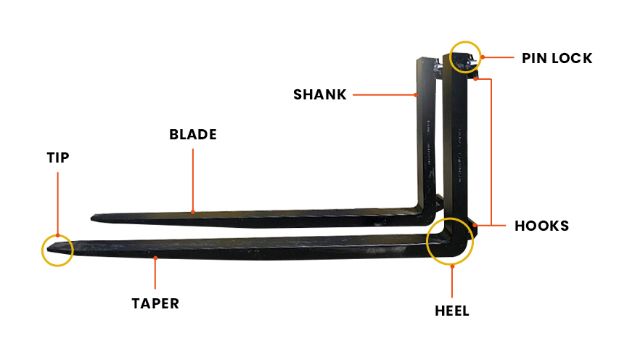

Understanding Forklift Tyne Terminology

Before choosing the right tynes, it’s essential to understand how they’re constructed and described. Here’s a quick breakdown of the key terms:

- Blade: The horizontal part that supports and lifts the load

- Tip: The front end of the blade that slides into pallets

- Shank: The vertical section connecting the blade to the carriage

- Heel: The curved intersection where the blade meets the shank

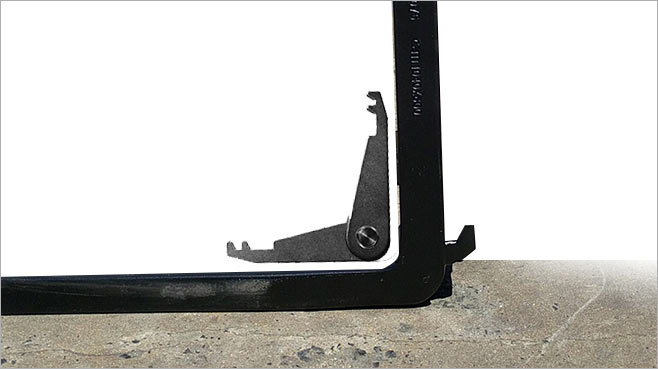

- Hook: Attachment points that allow the tynes to mount onto the carriage

- Locking Pins: Secure the tynes in place on the forklift carriage

- Taper: The gradual decrease in thickness from heel to tip

How to Read Forklift Tyne Dimensions

Forklift tynes are generally specified using the format Width (W) × Thickness (T) × Length (L), plus the class of the forklift carriage.

Key dimensions include:

- Carriage Plate Height ©: Height of the forklift carriage where tynes mount

- Fork Drop (D): Distance from top of lower hook to ground

- Length (L): From the tip to the shank (e.g. 1,219mm, 1,829mm, 2,438mm)

- Width (W): Width of the blade section

- *Thickness (T):*Thickness of the shank

- Spread: Distance between outside edges of the two tynes

Understanding these measurements ensures correct fitting, capacity, and safety compliance.

Types of Forklift Tynes – Which One Do You Need?

Different applications call for different types of tynes. Here are some of the most common:

- Hook Tynes: Most widely used; mounted with a locking pin on a forklift carriage

- Pin or Bar Type Tynes: Found on larger machines and telehandlers, using a shaft for mounting

- Drum Handling Tynes: Designed with cut-outs to securely lift cylindrical drums

- Coil Handling Tynes: Chamfered inner edges to support coils

- Explosion-Proof Tynes: Stainless steel clad to prevent sparks in hazardous environments

- Food & Beverage Grade: Also stainless clad to meet hygiene and washdown requirements

- Lumber Tynes: Thin, wide blades for easy entry under stacks of timber

Choosing the right tyne type isn’t just about fit, it’s about safety, load stability, and operational efficiency.

Forklift Tyne Safety: What You Should Be Doing

Even if you’re using the right tynes, poor maintenance or unsafe practices can still lead to failure. Here are some key safety reminders:

Conduct Regular Visual Inspections

Before each shift, inspect for:

- Damage, cracks, or bends

- Wear at the heel if it’s worn by more than 10%, the tyne must be replaced

- Secure locking pins and proper positioning

Reminder: A 10% reduction in heel thickness can decrease load capacity by up to 20%.

Know the Rated Capacity

Never exceed the forklift or tyne’s rated capacity. Overloading compromises balance and can lead to tip-overs, which cause serious injuries or fatalities.

Evenly Distribute the Load

Always use both tynes when lifting. Uneven weight distribution increases the risk of sideways tip-over. Also, ensure the load sits flush against the backrest for maximum stability.

Never Use Tynes to Lift People

Forklift tynes are designed to carry loads, not people. Using them to transport individuals is extremely dangerous and a clear safety violation.

Service and Maintain Correctly

Only qualified technicians should inspect, service, or modify tynes. Never drill, weld, or alter the tynes yourself this weakens their structural integrity.

Final Thoughts: Are Your Tynes Fit for Purpose?

Using the correct forklift tynes for your application and maintaining them properly is essential to both productivity and safety in any materials handling operation.

Whether you’re moving pallets, drums, coils, or timber, selecting the right type of tyne ensures safe lifting, protects your assets, and extends the life of your equipment.

Need help identifying or replacing your forklift tynes?

Explore our online specials via the Adaptalift Store, or contact our expert team on 13 22 54 for tailored advice and fast supply across all major forklift brands.

With service workshops in most capital cities and a national fleet of mobile technicians, we also offer full repair, servicing, and customisation of forklift tynes on-site or in the workshop.