How to Park a Forklift Safely

At the end of every shift it is important that all operators shutdown their forklifts correctly and park them in a safe place overnight.

In this blog we briefly look at the criteria that needs to be considered when choosing the safest place to park a forklift and the correct procedure for parking a unit.

Criteria for Selecting a Safe Forklift Parking Area

It is important to select a safe and appropriate area to reduce the likelihood of causing damage or injury.

It can be very easy to create a safety problem by parking a forklift in the wrong area.

Below is a list of inappropriate parking areas for forklifts:

1. Blocking any exit including emergency exists or in a place that prevents the exit from being fully opened

For health and safety it is imperative that the forklift isn’t parked blocking any exits particularly emergency exists.

In the event of an emergency such as fire staff need to exist a premises swiftly and don’t need the additional hindrance of having to find keys, start up and move a forklift out of the way of the exit.

2. Blocking any passageway even if it is only partially

Parking a forklift even partially across a passageway can cause disruption to employees walking whilst carrying heavy goods.

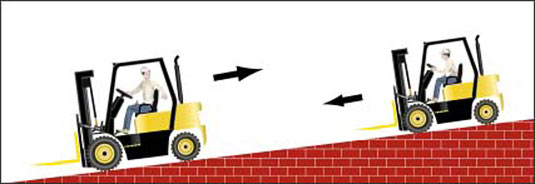

3. On a ramp or incline

If a forklift is parked on a ramp or incline there is a small chance the handbrake failing and the unit rolling away with momentum potentially causing damage to the surrounding area or unexpected injury to those working around the forklift.

If the only available safe parking space for the forklift is on a ramp or incline it is imperative that the wheels are chocked to reduce the likelihood of the unit rolling away.

4. Where other vehicles need to drive around the forklift

Forklifts are safest when parked away from areas where other vehicles operate.

If a forklift is parked in an area where other vehicles there is a heightened chance for collisions that cause damage to the forklift and/or the other vehicle from occurring.

5. Where other vehicles may come into contact with the forklift

Another common mistake made is parking a forklift next to industrial bins, dumpsters or skips, if a truck arrives to empty or pick-up the forklift parked near can obstruct access.

Collection can be delayed whilst the forklift is moved or even skipped if no one is on-site to move the forklift at the time of collection.

6. Near or obstructing a first aid station

Similar to obstructing an emergency exit, in the event of a medical incident quick access is required to a first aid station to treat injuries or potentially save an employee’s life.

A forklift obstructing access to the first aid station and vital medical supplies may have major detrimental effects to the injured employee receiving vital lifesaving treatment in the worst case scenario.

7. Next to a source of heat

Leaving a forklift next to a constant source of heat overnight can have a detrimental effect on the unit’s components as they may be burned or melted.

Burnt or melted parts of a forklift can easily lead to larger problems including full blown fire incidents if they aren’t immediately extinguished.

Forklift Parking Procedure

Once a safe parking area for the forklift has been located, operators must never leave a forklift in a condition or position where there is the potential for it to cause damage or injury.

When parking a forklift it is recommended the following procedure is followed:

1. Stop the forklift and apply the handbrake

Operators must apply the handbrake when vacating the forklift to prevent it from inadvertently moving uncontrolled potentially causing damage or injury.

2. Fully lower the carriage and tynes

3. Tilt the mast forward so the tyne tips are touching the ground

Due to their length a forklift tynes are a large potential trip hazard when raised.

Completely lowering the unit’s carriage and tynes to the floor as mentioned in the above steps two and three minimises the risk of those walking near the forklift from tripping over the tynes.

4. Turn the key or keyless switch to the ‘off’ position

By turning off the key or keyless switch stops power running to the forklift.

This reduces the risk of the unit moving unexpectedly if the operator accidently presses the accelerator pedal whilst exiting the cabin.

5. Release the units seatbelt and safely dismount from the operator cabin

6. If the forklift is battery electric connect the charger cables for overnight charging

If the forklift is a battery electric model to ensure it is ready to begin the next day’s shift it can be left connected to charge overnight.

Need help in determining where the safest place is to park your forklift?

One of our materials handling experts can come out and conduct a site survey to assess suitable parking positions for your unit.

Contact us on 13 22 54 or fill out a contact form and we will respond as soon as possible.