How to Reduce and Prevent Damage to Your Forklift

A key part of looking after a forklift is being able to prevent or reduce the likelihood of any damage occurring to the forklift that could adversely affect its operation and safety.

This week’s blog explores seven ways owners and operators can reduce or prevent damage to their forklifts from occurring.

1. Complete Regular Maintenance

Similar to a car all forklifts need to undergo regular servicing and maintenance at set manufacturer intervals.

Below a couple of examples of routine forklift maintenance are discussed demonstrating how it reduces and prevents damage to a forklift.

As part of regular maintenance common it is important that the unit’s fluid levels (e.g. engine or hydraulic oil) are checked and refilled where necessary, failure to have enough fluid in the machine can adversely affect and severely damage the engines or hydraulic systems resulting in costly repairs or even complete unit replacement in the future.

A forklift’s mast chains are one of the most integral components of the whole unit, chains need to be regularly lubricated to ensure they move smoothly whilst raising and lowering the mast.

Proper lubrication also reduces the likelihood of the chains rusting and losing their integrity raising the chances they may break under the strain of a lifting a heavy load.

2. Install Weather Protection

For forklifts that operate outdoors in weather conditions such as rain, snow or ice one of the easiest ways to prevent or reduce damage from the elements is to install some form of weather protection.

Weather protection may range from purchasing a forklift with a fully enclosed cabin like the Hyster Vista cabin or PVC curtains that can be retrofitted that not only protect the dashboard, controls and electronics from water ingress and damage but also the operator during inclement weather.

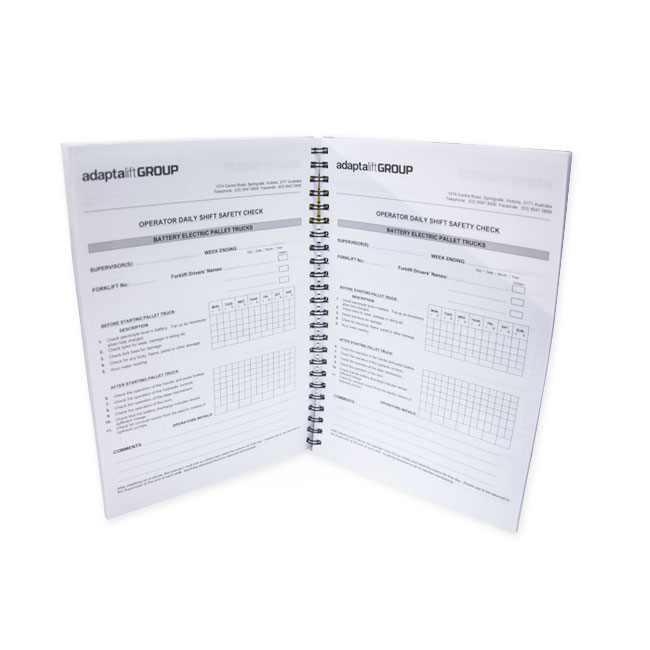

3. Conduct Pre and Post Start Checks

At the start of each shift it is imperative that pre and post start checklists are conducted.

Included in pre-start checklists are visual forklift inspections, checking the levels of common consumables are correct and that all safety features such as lights are working correctly.

Pre and post start checks are vital in the prevention of damage to forklifts as any physical damage, incorrect consumable levels and safety features that aren’t working are discovered before the unit starts operations.

The unit can be unsafe unit can be removed from operation until all faults have been resolved so they don’t further degrade and become worse over time.

4. Be Aware of Surroundings

Another simple way to reduce and prevent damage to a forklift is ensuring operators are aware of their surroundings in the operational area.

Hazards in the area may include vertical obstructions such as mezzanine levels, low height doorways or stock pallets left in the pathway or aisles.

If a forklift were to hit any of these obstructions it may result in not only damage to the unit but also to the load being carried or to property.

5. Operator Behavior

Ensuring that only properly trained and licensed employees are operating forklifts is another way to reduce and prevent the likelihood of damage to a forklift.

Licensed operators have been properly trained in forklift operation and are able to respond in a timely and safe manner in the event of an emergency or unit malfunction.

6. Don’t Drag Forklift Tynes

It is important to raise a forklifts tynes whenever it is in operation, dragging the tynes along the ground causes unnecessary physical damage to the tynes.

Continually dragging tynes along the ground also reduces their thickness which will gradually degrade their structural integrity and ability to safely lift heavy loads.

7. Don’t Overload the Forklift

All forklifts have a prescribed safe lifting capacity specified by the manufacturer.

The higher the mast can lift the load the safe lifting capacity decreases to ensure the unit keeps its centre of gravity and doesn’t become unstable heightening the chances of it tipping over.

It is imperative that operators know the safe lifting capacity of the forklift their operating and the load weights they’re lifting at all times to keep the unit stable and reduce the likelihood of a unit tipping over and possibly causing severe damage to the unit, operator, load or the surrounding areas.

This week’s blog has briefly discussed seven common ways to reduce and prevent damage occurring to a forklift.

With eleven branches within our national network and a large fleet of qualified and highly experienced mobile forklift technicians Adaptalift Group are able to service and complete all forklift damage repairs.

We also have a large range of forklifts and materials handling equipment available for short-term rental to fill any voids in customer operations whilst forklifts are being serviced or repaired.

To book a forklift service or repair contact a member of our service team on 13 22 54 or fill-out a contact form and we will reply as soon as possible.